1. Conduct a Thorough Daily Inspection

Start each day with a comprehensive inspection of your solar pile driver. Check for any visible signs of wear and tear, loose bolts, or other potential issues.

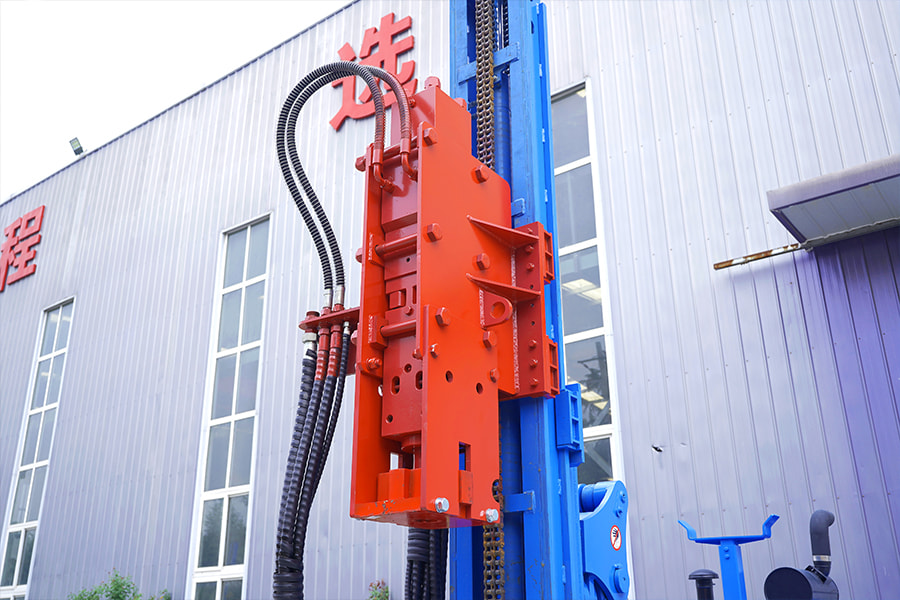

Pay close attention to the hydraulic system, pile hammer, and other critical components. Identifying problems early can prevent more serious damage and costly repairs.

2. Check Hydraulic Fluid Levels

The hydraulic system is the lifeblood of your solar pile driver. Ensure that hydraulic fluid levels are checked daily and topped up as needed. Low fluid levels

can lead to inefficient operation and potential damage to hydraulic components. Also, inspect hydraulic hoses and connections for leaks or damage.

3. Lubricate Moving Parts

Proper lubrication is crucial for the smooth operation of your solar pile driver. Ensure all moving parts, including the pile hammer and guide, are

well-lubricated. Use the recommended lubricants and follow the manufacturer's guidelines for frequency and quantity. This reduces friction and

wear, extending the lifespan of your equipment.

4. Monitor and Maintain Air Filters

Air filters play a vital role in maintaining the efficiency of your solar pile driver. Inspect and clean air filters daily to ensure they are free from dust

and debris. Clogged air filters can lead to reduced engine performance and increased fuel consumption. Regular cleaning helps maintain optimal performance.

5. Inspect the Pile Hammer and Guide

The pile hammer and guide are critical components of your solar pile driver. Check them daily for signs of wear and damage. Ensure that the pile hammer is

aligned correctly and that the guide is free from obstructions. Proper maintenance of these components ensures efficient operation and prevents damage to

the pile driver.

6. Check Fuel and Oil Levels

Before starting any operation, check the fuel and oil levels. Low fuel levels can cause the engine to run inefficiently, while low oil levels can lead to engine

damage. Use high-quality fuel and oil as recommended by the manufacturer to keep your pile driver running smoothly.

7. Examine the Electrical System

The electrical system is vital for the operation of your solar pile driver. Check the battery, wiring, and connections daily to ensure they are in good condition.

Look for signs of corrosion, loose connections, or damaged wires. A well-maintained electrical system ensures reliable performance and reduces the risk of

unexpected breakdowns.

8. Test Safety Features

Safety is paramount when operating a solar pile driver. Test all safety features, including emergency stop buttons, alarms, and protective guards, to ensure

they are functioning correctly. Regular testing and maintenance of safety features protect operators and prevent accidents on the job site.

9. Clean the Pile Driver

Keeping your pile driver clean is an often-overlooked aspect of maintenance. Dirt and debris can cause unnecessary wear and tear on moving parts. After

each day's work, clean the pile driver thoroughly, paying special attention to the air filters, cooling system, and engine bay. A clean rig operates more

efficiently and is easier to inspect for potential issues.

10. Maintain a Detailed Log

Keep a detailed log of all maintenance activities, including inspections, repairs, and replacements. This log helps track the condition of your pile driver

and schedule preventive maintenance. A well-documented maintenance history can also be useful for troubleshooting issues and making informed

decisions about equipment upgrades or replacements.

Arctic weather ahead! Your excavator struggling? Don't worry - Hengwang's got your back!

Arctic weather ahead! Your excavator struggling? Don't worry - Hengwang's got your back!

Title: Forklift Maintenance Guide: Boost Efficiency and Extend Lifespan

Title: Forklift Maintenance Guide: Boost Efficiency and Extend Lifespan

Eco-Friendly Underground Construction: Harnessing Horizontal Directional Drilling & Hengwang HWF460 Rig

Eco-Friendly Underground Construction: Harnessing Horizontal Directional Drilling & Hengwang HWF460 Rig