1. Soft Soil and Loose Aggregates

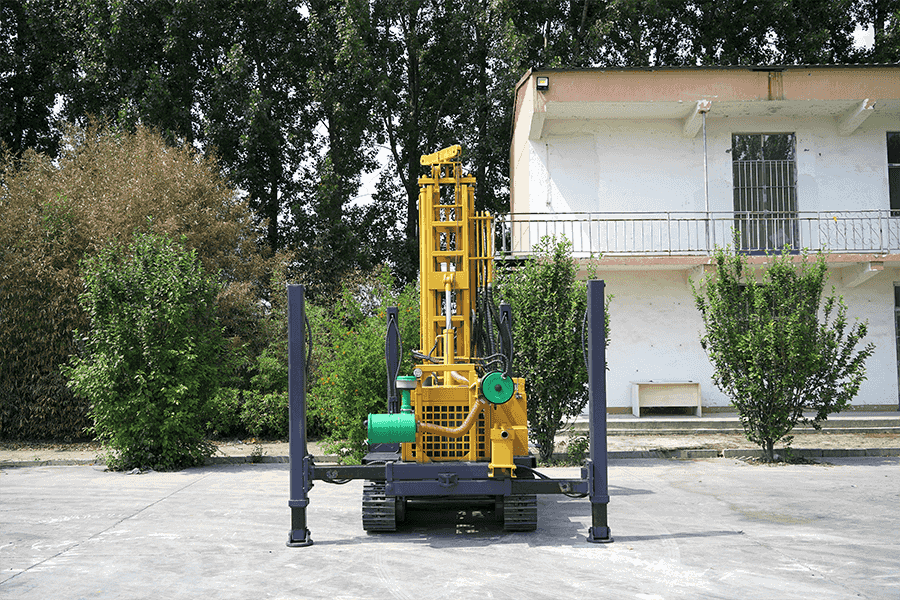

For sites with soft soil or loose aggregates, a lightweight and highly mobile pneumatic drilling rig is ideal. These conditions require

equipment that can handle frequent relocations and provide fast drilling speeds without compromising stability.

Recommended Features:

High mobility and easy transportation.

Efficient air compressor for rapid drilling.

Adjustable drilling speeds to adapt to varying soil conditions.

2. Clay and Silty Soils

Clay and silty soils can present challenges such as clogging and reduced penetration rates. In such cases, a pneumatic drilling rig

with robust torque and enhanced flushing capabilities is essential to maintain productivity and prevent blockages.

Recommended Features:

Powerful air compressor with high flushing capabilities.

Adjustable torque settings to handle varying resistance.

Anti-clogging drill bits designed for clay and silty conditions.

3. Sandy Soils

Sandy soils require drilling rigs that can maintain stability and prevent hole collapse. Look for models with features that

support efficient operation in loose and granular conditions.

Recommended Features:

Stabilizing systems to prevent hole collapse.

Efficient dust control and extraction systems.

High drilling speeds to minimize the risk of hole collapse.

4. Hard Rock Formations

Drilling in hard rock formations demands equipment with maximum power and durability. Pneumatic drilling rigs for

these conditions should offer high penetration rates and the ability to withstand significant wear and tear.

Recommended Features:

High-powered air compressors for maximum penetration.

Durable and wear-resistant drill bits.

Reinforced construction to handle the stress of hard rock drilling.

5. Mixed Geological Conditions

For projects involving mixed geological conditions, flexibility is key. A versatile pneumatic drilling rig that can

adapt to various soil and rock types ensures seamless transitions and consistent performance.

Recommended Features:

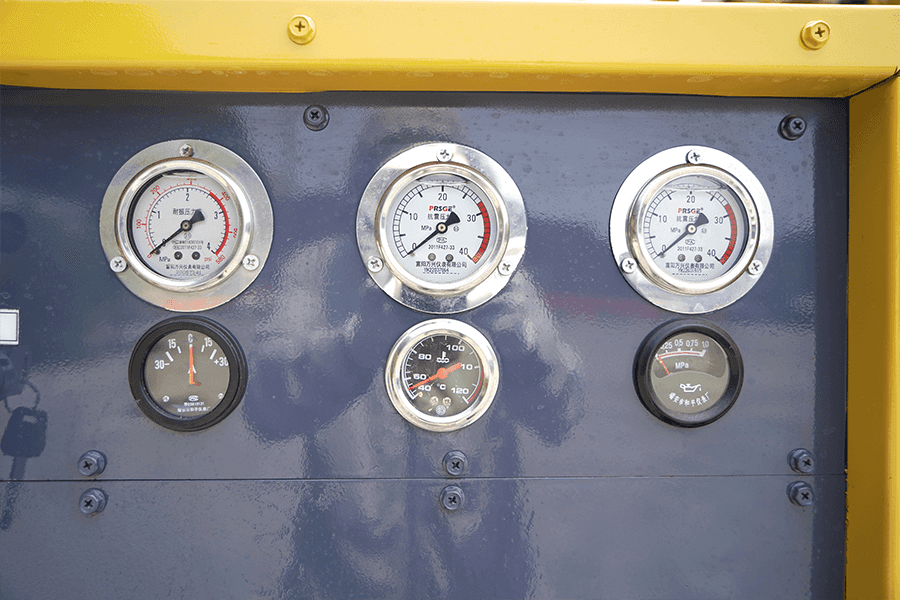

Adjustable settings for torque and drilling speed.

Versatile drill bits compatible with different soil and rock types.

Comprehensive control systems for precise adjustments.

Arctic weather ahead! Your excavator struggling? Don't worry - Hengwang's got your back!

Arctic weather ahead! Your excavator struggling? Don't worry - Hengwang's got your back!

Title: Forklift Maintenance Guide: Boost Efficiency and Extend Lifespan

Title: Forklift Maintenance Guide: Boost Efficiency and Extend Lifespan

Eco-Friendly Underground Construction: Harnessing Horizontal Directional Drilling & Hengwang HWF460 Rig

Eco-Friendly Underground Construction: Harnessing Horizontal Directional Drilling & Hengwang HWF460 Rig