Core Functions of Pile Drivers in Construction

Foundation Reinforcement:

Supports end-bearing piles (transmitting loads to stable strata) and friction piles (relying on soil adhesion) for structural stability.

Critical in high-rise buildings, industrial complexes, and soft-soil regions to prevent uneven settlement and enhance seismic resistance.

Versatile Applications:

Used for prefabricated piles, drilled shafts, and blasting-driven piles in frameworks exceeding 20m depth.

Essential for solar farms, photovoltaic installations, and urban developments requiring deep foundation support.

Pile Driver Working Principles

Impact-Driven Systems:

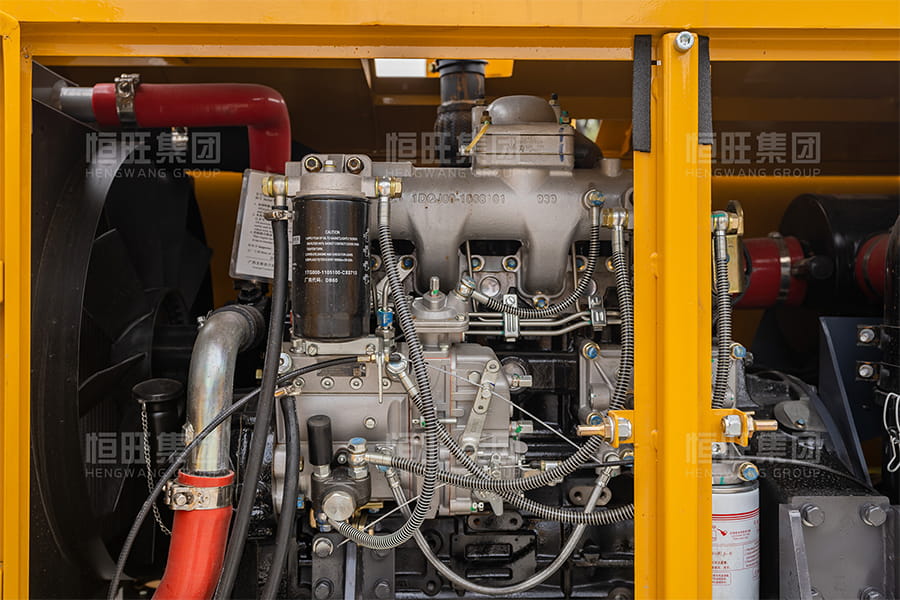

Diesel Hammer Pile Drivers: Utilize combustion energy to lift and drop weights, generating impact force to drive piles into dense soils.

Hydraulic/Vibratory Models: Employ high-frequency oscillations to reduce soil friction, enabling smooth penetration in softer layers.

Solar & Photovoltaic Adaptations:

Solar Pile Drivers: Leverage renewable energy for off-grid operations, reducing carbon footprints while maintaining power efficiency.

Photovoltaic Pile Drivers: Designed for solar farm installations, combining vibration technology with energy-storage systems for continuous operation.

Key Components & Operational Workflow

Structural Design:

Tower Frame: Steel-gantry structure with vertical guides for directional accuracy.

Hoisting System: Winch-controlled lifting of piles and hammers, adaptable for Inclined Pile / Battered Pile (angled piles) or underwater applications.

Advanced Features:

Automated rotation and mobility for multi-angle adjustments.

Real-time monitoring of kinetic energy, impact frequency, and penetration depth.

Innovations by Hengwang Group

Hybrid Power Modes: Solar-electric hybrids for urban projects and rugged Diesel -electric systems for remote sites.

Eco-Conscious Engineering: Noise reduction, vibration control, and energy recycling align with green construction standards.

Smart Automation: AI-driven diagnostics and IoT connectivity for predictive maintenance and operational optimization.

By merging Pile Driver reliability with Solar and Photovoltaic advancements, Hengwang Group redefines foundational engineering for a sustainable future.

Arctic weather ahead! Your excavator struggling? Don't worry - Hengwang's got your back!

Arctic weather ahead! Your excavator struggling? Don't worry - Hengwang's got your back!

Title: Forklift Maintenance Guide: Boost Efficiency and Extend Lifespan

Title: Forklift Maintenance Guide: Boost Efficiency and Extend Lifespan

Eco-Friendly Underground Construction: Harnessing Horizontal Directional Drilling & Hengwang HWF460 Rig

Eco-Friendly Underground Construction: Harnessing Horizontal Directional Drilling & Hengwang HWF460 Rig