Hydraulic Drilling Rig Maintenance & Troubleshooting

Hydraulic System Fundamentals

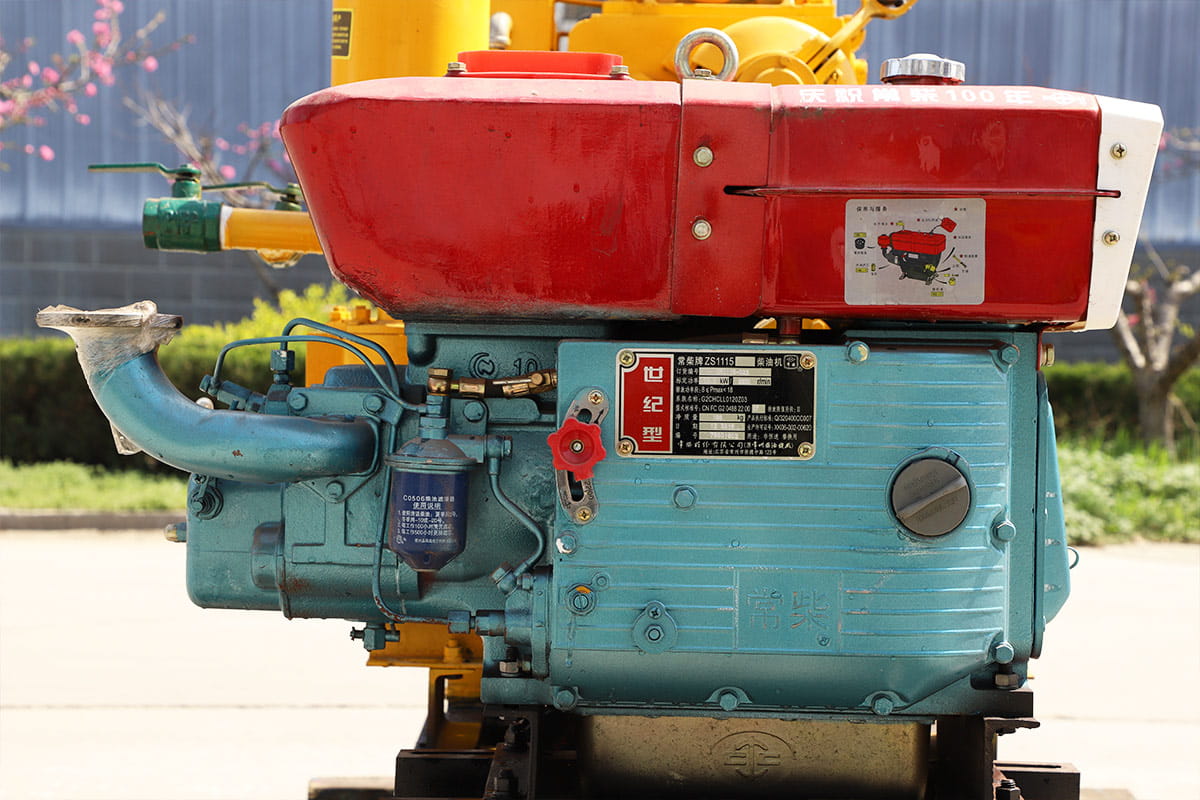

Converts mechanical energy into pressurized fluid power via pumps, valves, and actuators to drive drilling operations.

Hengwang Group’s Innovation: Enhanced pressure regulation systems minimize energy loss and component wear.

Advantages of Hydraulic Drilling Technology

Power Density: Compact components deliver high torque for deep Core Drilling Rig applications.

Precision Control: Closed-loop systems ensure minimal positioning errors during water well drilling.

Rapid Response: Hydraulic actuators enable quick adjustments in challenging terrains.

Key Maintenance Practices

Oil Quality Management:

Monitor viscosity, acidity, and contamination levels monthly; replace filters every 500 operating hours.

Use high-grade anti-wear hydraulic oil to prevent sludge formation.

Component Inspection:

Check pump seals and valve spools for leaks during routine servicing.

Lubricate bearings and gears in Water Well Drilling Rigs to extend lifespan.

Temperature Control:

Install cooling systems to maintain oil temperatures below 55°C, preventing thermal degradation.

Common Faults & Solutions

Loss of Pressure:

Causes: Clogged filters, worn pump seals, or air ingress.

Fix: Clean/replace suction filters; bleed air from hydraulic lines.

Erratic Movements:

Causes: Contaminated fluid or valve blockages.

Fix: Flush systems with cleaning agents; recalibrate control valves.

Overheating:

Causes: Excessive load, insufficient cooling, or degraded oil.

Fix: Reduce workload; inspect heat exchangers; replace oil.

Hengwang Group’s Technical Enhancements

Smart Diagnostics: IoT-enabled sensors in Core Drilling Rigs provide real-time wear analytics.

Eco-Friendly Design: Noise-dampened Water Well Drilling Rigs for urban deployments.

Modular Components: Quick-swap hydraulic packs reduce repair downtime.

By integrating cutting-edge Hydraulic Drilling Rig systems with specialized Water Well and Core Drilling capabilities, Hengwang Group redefines reliability in modern drilling operations.

Arctic weather ahead! Your excavator struggling? Don't worry - Hengwang's got your back!

Arctic weather ahead! Your excavator struggling? Don't worry - Hengwang's got your back!

Title: Forklift Maintenance Guide: Boost Efficiency and Extend Lifespan

Title: Forklift Maintenance Guide: Boost Efficiency and Extend Lifespan

Eco-Friendly Underground Construction: Harnessing Horizontal Directional Drilling & Hengwang HWF460 Rig

Eco-Friendly Underground Construction: Harnessing Horizontal Directional Drilling & Hengwang HWF460 Rig