Key Considerations for Pneumatic Water Well Drill Bit Usage

Post-Drilling Tool Management

Clean borehole residues thoroughly using compressed air before extracting the drill string to prevent jamming.

Gradually lift the bit once rotation stops, ensuring lifting force aligns with tool weight to avoid equipment strain.

Real-Time Monitoring & Maintenance

Track casing advancement and borehole integrity via sensors to detect irregularities (e.g., rock debris accumulation).

Avoid forced extraction during drilling; instead, apply controlled torque adjustments to resolve minor blockages.

Residual Rock Debris Mitigation

Use air-flushing systems to clear compacted cuttings around eccentric bits, restoring rotation efficiency.

Activate down-the-hole (DTH) hammers briefly to fracture stubborn strata, easing tool retrieval.

Drill Bit Selection & Handling

Choose carbide-tipped or diamond-core bits based on lithology to minimize wear and enhance coring accuracy.

Inspect bits pre-use for cracks or blunt edges; replace if defects exceed 2mm depth.

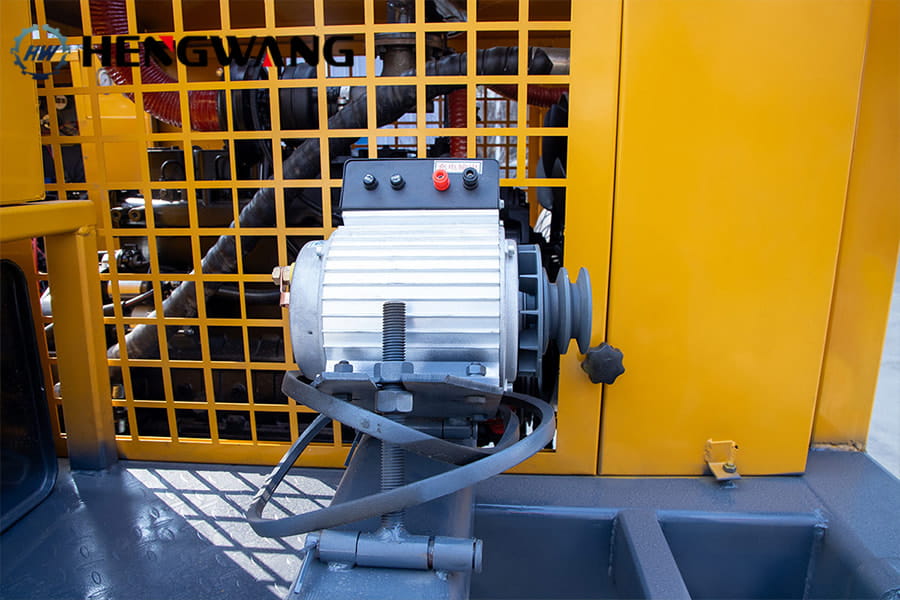

Hengwang Group’s Technical Innovations

Smart Cooling Systems: Reduce thermal stress on pneumatic rig components by 30%, extending bit lifespan.

Modular Drill Heads: Swap between rotary, percussive, or hybrid modes for adaptable drilling in mixed geology.

Eco-Compliance: Low-emission rigs meet urban noise (<75 dB) and particulate emission standards.

Drilling Best Practices

Lubrication Protocols: Apply biodegradable grease to bit bearings every 8 operating hours to prevent seizure.

Depth Calibration: Adjust feed pressure dynamically using load sensors to maintain 0.5–1.2 m/h penetration rates.

Emergency Response: Deploy anti-jamming algorithms in automated rigs to halt operations during overloads.

By leveraging water well drilling machine reliability and pneumatic drill rig agility, Hengwang Group empowers sustainable resource exploration with precision-engineered rigs for drilling.

Arctic weather ahead! Your excavator struggling? Don't worry - Hengwang's got your back!

Arctic weather ahead! Your excavator struggling? Don't worry - Hengwang's got your back!

Title: Forklift Maintenance Guide: Boost Efficiency and Extend Lifespan

Title: Forklift Maintenance Guide: Boost Efficiency and Extend Lifespan

Eco-Friendly Underground Construction: Harnessing Horizontal Directional Drilling & Hengwang HWF460 Rig

Eco-Friendly Underground Construction: Harnessing Horizontal Directional Drilling & Hengwang HWF460 Rig